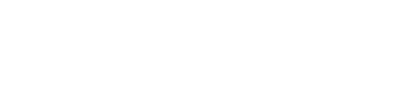

A steelworker watches molten steel in Scunthorpe (LINDSEY PARNABY/AFP via Getty Images)

In 1859, a north Lincolnshire landowner named Rowland Winn discovered that under his land lay a valuable commodity. After digging it up, he sold 500 tons of the stuff to a Barnsley ironmaster — and Scunthorpe’s die was cast. This remote rural locality would become one of England’s engine-rooms — and the home of British Steel.

A few years after Winn’s excavations, the first furnaces were built, and the Domesday hamlet of Scunthorpe started producing pig-iron. The borough’s old crest features a blast furnace belching flames, with the redolent motto: “The Heavens Reflect Our Labours.” Soon, the county’s companies started turning the iron into steel. By the end of the First World War, Scunthorpe produced 3% of the UK’s steel, some of it armouring the first military tanks, invented in Lincoln; by the start of the Second, it was producing 10%, some of it used in D-Day landing craft.

Since then, Scunthorpe metal has gone into everything from Sydney Harbour Bridge to the London Eye. But this elemental industry is rusting away. British Steel has recurred in the last decade’s headlines, almost always linked to job losses. Now, up to 800 of its remaining 3,200 steel jobs are at risk — a painful reversal for Lincolnshire.

Scunthorpe’s steel was for many years a magnet, attracting workers from all over Britain, and sometimes overseas — Germans before the Second World War, Eastern Europeans afterwards, Asians in the Seventies. In 1960, almost a third of Scunthonians (around 20,000) were directly employed in steel. A BBC documentary from that year, Scunthorpe is Booming, shows a town of bustling streets, with optimistic interviewees talking about all the things they could buy thanks, directly or indirectly, to steel — cars and foreign holidays and “tellies” — although a few did express reservations about the social effects of all this dynamism. Industries sprang up to cater to steel’s ever-lengthening supply chains, and all these new consumers — including Golden Wonder crisps. (Some locals claim the cheese and onion flavour was invented in the town.)

It was Steve Cook who cast Scunthorpe’s last ingots, in 2000. He started at British Steel in 1968 with just four O-levels, and retired in 2007, having risen to the rank of Quality Manager. Sitting in his immaculate house within earshot of the furnaces, he exudes quiet pride: “Scunthorpe was renowned for making one of the best steels in the world, and the name British Steel was synonymous with quality.” He recalls an avuncular employer, which sponsored his studies in metallurgy, then provided a job for life. The town, he remembers fondly, largely revolved around shift-times, with hooters announcing shift-changes. Streets would fill with men on bicycles and then as suddenly empty again, an almost instinctive mass movement of those who were busily forging the future. Now the town’s commuters, faces fixed to their phones, are living in worlds of their own.

Not everyone enjoyed their time working in Scunthorpe steel. Conditions were hazardous in the early days. In the 19th and early 20th centuries, steelworkers would work 12-hour weekday shifts, and 24-hour shifts on alternate Sundays, with no extra pay even on Christmas Day. Veterans of the Twenties recalled their lunches being layered with fine iron grit. There were frequent accidents: on the worst day, in 1975, 11 workers died when one of the town’s iconic “Four Queens” furnaces blew up. As recently as 2021, a fireball erupted unexpectedly at the British Steel works, although luckily no-one was hurt. Last year, a 27-year-old worker was killed falling from a crane.

And not all the social impacts of the works were positive. Influxes of large numbers of young single men, and the Tartarean thirstiness of their work, resulted in problems with public drunkenness; as early as 1860, extra constables had to be drafted in. Employers took a zero-tolerance approach, with workers liable to be sacked if they had any alcohol on their breath — except for one steelworks, which ran what must have been a highly lucrative “wet canteen” into the Seventies.

A community spirit nevertheless emerged, grounded in shared experience and Methodist morality (nearby Epworth was John Wesley’s birthplace), and reinforced by institutions. Technical colleges and grammar schools, a hospital, a theatre, and an array of social and sporting clubs all began to appear, most famously Scunthorpe United, founded in 1899, and nicknamed “The Iron”. Workers wistfully recall a steely solidarity, with its own vocabulary — casters, feedstocks, gangue, sinter, trunnion — and a confidence borne of mastering dangerous elements for their own and everyone’s benefit. Steelworkers took on an almost mythic quality at times in the popular imagination, brilliantly skilled men silhouetted against incandescent orange, controlling leviathan cranes that swung 130-tonne ladles filled with 280 more tonnes of molten menace. Today’s call-centres, industrial parks, and offices are pallid by comparison.

When British Steel was born, in 1967, as the British Steel Corporation (BSC), there was much excitement about “the white heat of technology”. Innovations would, it was argued, remould the tired old post-imperial country. BSC emphasised quality over quantity, investing constantly in technical research. Britain had always been a world-leader in steel — but the pace of change had sped up. Some of the cars snapped up by Scunthorpe’s happy Sixties shoppers would have weighed a ton and a half of mostly British-made steel, but cars were becoming steadily lighter and smaller. There was less and less demand for Scunthorpe’s product, even before the whole motor industry went into the doldrums, along with British shipbuilding.

Then as now, successive governments failed to capitalise on British technical ingenuity. Ted Heath hoped that the new local authority of “Humberside”, into which Scunthorpe was lumped in 1974, might be an English Ruhr. But BSC always found itself fighting, often unavailingly, against cheaper Asian imports and other countries’ tariffs. The would-be Ruhr sometimes seemed at risk of becoming more of an American-style rust belt.

Enter: the Iron Lady. In the first two years of her reign, Margaret Thatcher appointed the uncompromising Ian MacGregor as chairman of BSC. Two of Scunthorpe’s four ironworks were closed. A December 1979 announcement of swingeing cuts at Scunthorpe was dubbed “Mr MacGregor’s sick Christmas card” by the town’s mayor, and led to a 13-week strike. But MacGregor was up for a fight, and ultimately, he won. In 1980, BSC had employed 166,000 nationwide, and lost £1.8 billion every year; by the time MacGregor left in 1983, it employed 71,000, and annual losses had been cut to £256m. In 1985, it recorded its best results since the Sixties. Scunthorpe was a crucible of a new economic order, melted and remade by monetarism — but there was a human cost, as in the mining communities of the North. Unemployment nationwide was almost three times what it is now.

Meanwhile, the nation was losing its grip on the industries that built it. Now a profitable company, BSC was privatised, before being absorbed into the British-Dutch Corus Group — the biggest steelmaker in Europe and the third-largest in the world. Corus was itself taken over, just in time for the financial crash, by the Indian firm Tata, which ended up selling it in 2016 to a venture capital firm for £1. After reintroducing the nostalgic name, the firm sold the plant on in 2019 to China’s Jingye Group, which now operates as British Steel. With every takeover, hundreds of jobs were lost; since 2007, Scunthorpe’s annual steel production has halved from 5m to 2.5m tonnes. This most substantial of great British industries is now forced to trust in overseas investors with no stake in the borough, and its rooted community relies on boardroom decisions in Beijing. Britain’s steel production is, after all, something of an afterthought from a Chinese perspective; in 2019, the UK produced just 7m tonnes of steel, compared with the 996m made in China.

The now barely British British Steel, reeling under high energy costs, is a pressure point for the Government. On the one hand, there is the wish to protect jobs in a “Red Wall” seat, won for the Conservatives in 2019 by the granddaughter of a steelworker. On the other, there is a national commitment to Net Zero carbon emissions, and steel accounts for around 14% of UK industrial emissions. Recently, British Steel has threatened to shed at least 260 jobs at Scunthorpe, and maybe as many as 800 — a quarter of all the jobs left — unless the Government gives it money to invest in greener electric furnaces. The Government has offered £300m, but negotiations appear to be foundering, because the money is thought insufficient, and comes with preconditions about guaranteeing employment for a decade. If all these Scunthorpe jobs do go, many Scunthonians fear they would be followed inexorably by others.

The Government claims to be committed to the industry, although support sometimes seems uncertain, and no new measures were announced in the latest budget. Steel does not contribute much directly to the UK economy — just £2 billion in 2020, when it accounted for 1.2% of manufacturing output and 0.1% of UK jobs. Still, there is strong ongoing and projected demand for steel — for projects ranging from HS2 to healthcare, flood defences to the military — and much of it could be produced here. Better to have our needs met in Scunthorpe than Baoshan, surely.

Industry veterans are sceptical about the Government’s Net Zero priorities. David Amoss, who spent 30 years working in Scunthorpe, points out: “The steel’s still got to be made and it may as well be made in Scunthorpe as in the Far East. I find this carbon footprint thing an absolute distraction and a nonsense. Not that I don’t believe we’re destroying our own planet, but if we don’t do it someone else is going to.” Steel that is not made here will just be made in another country, perhaps one with weaker environmental safeguards, and boosting their economy instead of ours. Steve Cook concurs: “From a global point of view, it’s just shifting the problem elsewhere.” Besides, closing down both furnaces could cost more than £1 billion.

Manufacturing has long been a victim of modern Britain’s focus on service industries over making things the world both needs and wants. “If steel does go, as a manufacturing country we’re buggered,” says Amoss. “I fail to understand how any country can really exist with any sort of wealth if it doesn’t make anything and consumes a lot.” To those who built their lives around industries like steel, today’s Britain can seem an unkind as well as unwise country, ungratefully casting off its past and recklessly mortgaging its future in the interests of expedience and profit.

The story of steel in Scunthorpe is unique, but it echoes that of the North’s, or Wales’s, mining communities. Our nation is replete with towns like this: so strongly associated with its industry that it is almost impossible to envisage existence without it. After 150 years of unglamorous and unrelenting endeavour, Scunthorpe’s whole reason-to-be has suddenly become ethically suspect, its Britain-building citizens at risk of being abandoned. Can a forward-looking national realism, drawing on an old sense of obligation, compete with today’s green and globalised agenda? This time-tempered town is not the only one nervously awaiting an answer to that question.

Join the discussion

Join like minded readers that support our journalism by becoming a paid subscriber

To join the discussion in the comments, become a paid subscriber.

Join like minded readers that support our journalism, read unlimited articles and enjoy other subscriber-only benefits.

Subscribe